WE ARE IMPORTERS, STOCKISTS FOR ALL TYPES OF POWDER METALLURGY HIGH SPEED STEEL

POWDER METALLURGY HIGH SPEED STEEL ORIGIN MAKES:

- ERASTEEL ASP STEEL

- CRUCIBLE REX STEEL

- BOHLER S STEEL

- THYSSENKRUPP STEEL

- NACHI FAX STEEL

- ZAPP STEEL

- ASSAB STEEL

- HITACHI POWDER STEEL

- POWMEX GRAPHITE STEEL

GRADES:

PM 23, PM4, PM 30, PM 39, PM52, PM 60

SPECIFICATIONS / BASIC PARAMETERS

ROUND Dia:- Medium Dia: 12 mm to 160 mm

- Large Dia: 165mm to 380 mm

FLATS: (W) 10mm – 250mm to (H) 20mm – 100mm x Length

(Direct import only on client specific minimum qty order)

SQUARE BARS: 10 mm to 200mm (direct import only on client specific minimum qty order)

GRADES OF POWDER METALLURGY HSS

PM 23 Steel– (Powder HSS M2) also known as ASP2023 is a chromium- molybdenum-tungsten alloyed vanadium powder made HSS Suitable for blanking & forming of thinner work materials where abrasive type of wear is encountered. It is also known as Powder HSS M2.

| Grades | Average Chemical Composition % | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Aisi No. | Work No. | C. | Si. | Mn. | Cr. | Mo. | V. | W. | Co. | Oths. | |

| S790 | 1.3344 | ASP 2023 | 1.25 | 0.7 | 0.5 | 3.9 | 4.75 | 2.75 | 6.0 | 1.0 | Nb 0.5 |

| Applications: Milling cutters, broach needles cutting & punching, tools dies, working rolls for cluster rolling stand. | |||||||||||

PM4 Steel - (Powder HSS M4) also known as ASP4 is a high Vanadium-chromium- molybdenum-tungsten alloyed Powder based HSS steel Suitable where adhesive wear & chipping are the dominant problems occur such as SS, Mild steel, copper, aluminum or thicker work material

| Grades | Average Chemical Composition % | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Aisi No. | Work No. | C. | Si. | Mn. | Cr. | Mo. | V. | W. | Co. | Oths. | |

| S690 | 1.3351 | ASP 4 | 1.33 | 4.3 | 4.9 | 4.1 | 5.9 | ||||

| Applications: High speed steel produced by the powder metallurgy method for heavy duty machining tools e.g. for machining of nonferrous metals alloys, such as Ti-base & Ai-alloys. Tools exposed to high compressive stresses, e.g. in fine blanking tools for high-strength materials. | |||||||||||

PM 30 Steel - (Powder HSS M35) also known as ASP2030 is a very high performance Powder metallurgical material having a optimal high cobalt (8%) - vanadium-chromium- molybdenum-tungsten alloyed steel, Suitable for machining of nickel-base and titanium alloys, for heavy and interrupted cuts, such as gear hobs, shapers, milling cutters, twist drills, taps and broaching tools. 8% cobalt modification of M3 high speed steel. It has red hardness comparable to that of M42 but offers abrasion resistance even better than that of M3. With its excellent red hardness, good wear resistance and good toughness

| Grades | Average Chemical Composition % | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Aisi No. | Work No. | C. | Si. | Mn. | Cr. | Mo. | V. | W. | Co. | Oths. | |

| S590 | 1.3207 | ASP 2030 | 1.25 | 0.7 | 0.5 | 3.9 | 4.75 | 3.0 | 6.0 | 8.25 | Nb 0.50 |

| Applications: End mills, hobs, shaper cutters, cold forming tools, stamping & punching tools, cutting tools, working rolls for cluster rolling stand. | |||||||||||

PM 52 Steel - (Powder HSS T42) also known as ASP2052 is a very high performance Powder metallurgical material having a optimal high cobalt (8%)– high vanadium- high Tungsten(10%) -chromium- molybdenum alloyed steel, It is heat treatable to HRC 67-69. Its high carbon, vanadium and Cobalt contents provide abrasion resistance comparable to that of T15 and red hardness superior to that of M42. With its high hardness, fine grain size and uniform carbide distribution, it’s an outstanding choice for special purpose cutting tools requiring high red hardness, high abrasion resistance, and good toughness. Suitable for machining of nickel-base and titanium alloys, for heavy and interrupted cuts, such as gear hobs, shapers, milling cutters, twist drills, taps and broaching tools

| Grades | Average Chemical Composition % | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Aisi No. | Work No. | C. | Si. | Mn. | Cr. | Mo. | V. | W. | Co. | Oths. | |

| S390 | ASP 2052 | 1.6 | 4.8 | 2.0 | 5.0 | 10.5 | 8.0 | ||||

| Applications: High speed steel produced by the powder metallurgy method for heavy duty machining tools e.g. tools for nonferrous metals such as Ni-base & Ti-alloys. Tools used under extreme compressive stresses, e.g. precision blanking tools for high-strength materials. | |||||||||||

PM 60 Steel – also known as ASP2060 is the highest performance PM material among all the categories. With high cobalt - vanadium-chromium- molybdenum-tungsten alloyed steel. It is machinable & is available in few sizes only. Suitable for fast, high wear & chipping machinability, works with high graded steel aluminum, carbon contained alloys etc. Turning and milling tools for roughing and finishing work, wood working tools, highly stressed cold work tools, tool bits.

Introduction of PM STEEL

The Powder made steel formation process results in a homogeneous microstructure with a finer, more uniform carbide distribution imparting superior dimensional stability, grind ability and toughness when compared to steels produced by conventional processes. This process also allows the design of more highly alloyed grades which cannot be produced by conventional steelmaking

Powder Metallurgy formation of steel is highly costly since the process of annealing and forging via nitrogen technology is costly. Producing Various High speed steel grades via powder metallurgy formation process is completely different than already commonly used HSS conventional way via forging/annealing/hardening/ grinding route. With high demands from around the world

Nowadays, with huge demand of Powder HSS, Conventional HSS has started to get replaced by this Effective PM Steel. It has become a wide popular choice for various diverse applications for tooling in mechanical as well as in CNC. It is suitable for an ample variety of users that grind, not except operations with alloys of the high temperature and exotics.

With life of the tools as almost equal to twice, Due to high chemical composition of Cobalt, Vanadium, Tungsten, Nickel the steel grains stick to its properties stronger with offering us the best steel to be used for high performance tools.

Micro structure of Powder Metallurgy HSS bar material

Soft annealed, sintered in vacuum to full density, water atomized prealloyed powder (T42), Carbides in white, ferrous in grey

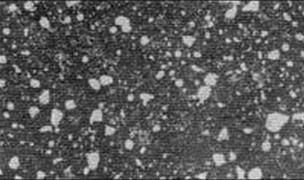

Compacted and hardened, sintered to full density in vacuum, annealed & water atomized T 15 powder. Carbides uniformly distributed in the metal. Carbides shown in white with dark steel background.

Micro Structure of Conventional High Speed Steel bar material

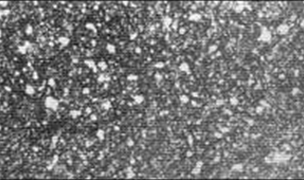

Hardened, cast and wrought high speed steel. Dark steel matrix background with Carbides shown in white