DISTRIBUTORS, IMPORTERS & STOCKISTS OF ALL GRADES OF HIGH SPEED STEEL

Introduction of HSS

As the name refers “HSS” High speed steel existence has been increasing each day due to today’s World modern industrial production. Formation of activities on mechanical & CNC mass production, tooling is one of the key factors pertaining for the performance of shaping and forming processes.

HSS GRADES:

MOLYBDENUM GRADES: M2, M3/2, M4, M35, M42

TUNGESTEN GRADES: T1, T4, T5, T15, T42

Introduction of HSS

In today’s World - for modern industrial production, particularly on mechanical & CNC mass production, tooling is one of the key factors pertaining for the performance of shaping and forming processes. Almost all tools employed for this purpose are made from high speed steels. The use of high speed steels has also gained increasing importance for chipless shaping, eg. for extrusion, blanking and punching tools.

HSS chemical composition distinctly differentiates between W-, Mo- and W-Mo alloyed steel grades, which contain different amounts of carbon, vanadium and cobalt elements to strengthen its own occurrence.

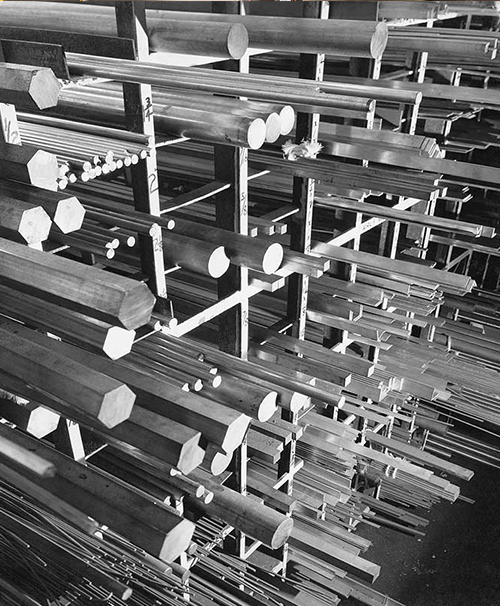

Sizes & Ranges of above HSS mentioned grades:

ROUND Dia:- Small Dia : 5mm to 63 mm

- Medium Dia: 65 mm to 160 mm

- Large Dia: 165mm to 350 mm

FLATS: (W) 10mm – 250mm to (H) 20mm – 100mm x Length (meters)

SQUARE BARS: 10mm to 200mm

POWDER METALLURGY HIGH SPEED STEEL ORIGIN MAKES:

- High working hardness

- High wear resistance

- High retention of hardness and red hardness

- Excellent toughness

Alloying elements present in HSS properties:

- Carbon : forms carbides, increases wear resistance, is responsible for the basic matrix hardness.

- Tungsten and molybdenum: improve red hardness, retention of hardness and high temperature strength of the matrix, form special carbides of great hardness.

- Vanadium: forms special carbides of supreme hardness, increases high temperature wear resistance, retention of hardness and high temperature strength of the matrix.

- Chromium: promotes depth hardening, produces readily soluble carbides.

- Cobalt: improves red hardness and retention of hardness of the matrix.

HIGH SPEED STEEL CHEMICAL COMPOSITION

| Chemical Composition | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | P | S | Cr | Mo | V | W | Co | Ni | |

| AISI M-2 | 0.78-0.88 | 0.20-0.40 | 0.20-0.40 | 0.35 | 0.35 | 3.75-4.50 | 4.50-5.50 | 1.60-2.20 | 5.50-6.75 | ||

| AISI M-35 | 0.85-0.95 | 0.00-0.40 | 0.00-0.40 | 0.35 | 0.35 | 3.75-4.50 | 4.75-5.25 | 1.75-2.15 | 6.00-6.75 | 4.60-5.20 | 0.00-0.40 |

| AISI M-42 | 1.05-1.15 | 0.15-0.65 | 0.15-0.40 | 0.35 | 0.35 | 3.50-4.25 | 9.00-10.00 | 0.95-1.35 | 1.15-1.85 | 7.75-8.75 | |

| AISI T-1 | 0.65-0.75 | 0.20-0.40 | 0.20-0.40 | - | - | 3.75-4.50 | - | 0.90-1.30 | 17.25-18.75 | ||

| AISI T-4 | 0.70-0.80 | 0.20-0.40 | 0.20-0.40 | - | - | 3.75-4.50 | 0.70-1.00 | 0.80-1.20 | 17.25-18.75 | 4.25-5.75 | |

| AISI T-5 | 0.75-0.85 | 0.20-0.40 | 0.20-0.40 | - | - | 3.75-4.50 | 0.70-1.00 | 1.80-2.40 | 17.50-19.00 | 7.00-9.00 | |

| AISI T-42 | 1.25-1.40 | 0.00-0.40 | 0.00-0.40 | 0.35 | 0.35 | 3.75-4.50 | 2.75-3.50 | 2.75-3.25 | 8.50-9.50 | 9.00-10.00 | 0.00-0.40 |

| HIGH SPEED STEELS-EQUAVALENT GRADES | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Grade | Standards | Applications | |||||||

| BOHLER | AISI | BS | IS | JIS | DIN | ||||

| T1 | S 200 | T1 | BT 1 | XT72W18 Cr4V1 | SKH-2 | S 18-0-1 | Turning, Planing and slotting tools, taps, twist drills, threading dies, profile cutting tools, broaching tools, reamers. | ||

| T4 | S 305 | T4 | BT 4 | XT75W18 Co5Cr4MoV1 | SKH-3 | S18-1-2-5 | Turning, Planing and milling tools, in particular for roughing work. | ||

| T15 | S 308 | T15 | BT 15 | - | - | S12-1-4-5 | Turning tools for finishing a precision-cutting work. Where max. Abrasion resistance and hardness retention and red hardness is required. | ||

| T42 | S 700 | - | BT 42 | XT125WCo10 CrMo4V3 | SKH-57 | S10-4-3-10 | Turning and milling tools for roughing and finishing work, wood working tools, highly stressed cold work tools, tool bits. | ||

| M 2 | S 600 | M2 | BM 2 | XT87W6Mo5 Cr4V2 | SKH-51 | S 6-5-2 | Taps, twist drills, reamers milling and broaching tools, metal saws, milling tools of all types, wood working tools, cold work tools. | ||

| M 3 CL2 | S 607 | M3 CL2 | BM 4 | - | SKH-53 | S 6-5-3 | |||

| M 35 | S 705 | M41 | BM 35 | XT90W6Co Mo5Cr4V2 | SKH-55 | S 6-5-2-5 | Turning, Planing tools of all types, milling cutters, broaches and hobs, taps, twist drills, wood working tools, cold work tools. | ||

| M 42 | S 500 | M42 | BM 42 | XT110Mo10 Co8Cr4W2 | SKH-59 | S 2-10-1-8 | Milling cutters, twist drills, taps, broaching tools, cold work tools. | ||

Steel Properties

- Standard grade for High Speed Steels; owing to its balanced composition has good toughness and cutting performance, hence many applications.

- HSS Containing cobalt content is a high performance steel with good cutting capability & ensures high red hardness and tempering retention. It is particularly suitable in thermal stress situations and for intermittent cutting.

- High Speed Steel with high molybdenum and carbon. It has high wear resistance, high red hardness and good toughness. With its low vanadium content, this grade has very good grind ability

APPLICATIONS

High performance Gear Cutting Hobs, Shapers, Milling cutters, Bevel tools, of all kinds of highly stressed twist bits and taps, shaped shear blades, for working high strength materials, broaches. Cutting tools for roughing or finishing, such as: helical bits, milling cutters of all types, taps, dies, spindles, reamers, thread rolling tools, drill bits, circular saw segments.

Impact tools and those used for working wood. Cold forming tools such as dies and punches for cold extrusion and cutting and fine cutting tools.

INDUSTRIES WE SERVE

- AIRCRAFT AND AEROSPACE INDUSTRY

- ENGINEERING AND CONSTRUCTION

- CHEMICAL INDUSTRY

- CEMENT PLANTS

- DEFENCE

- DRILLING AND WELL BUILDING

- DAIRY & FOOD INDUSTRIES

- FERTILIZER

- HEAT EXCHANGERS

- INSTRUMENTATION

- NUCLEAR POWER

- OIL AND GAS INDUSTRY

- PHARMACEUTICAL INDUSTRY & BIOCHEMISTRY

- PETRO CHEMICALS

- POWER PLANTS

- SHIP BUILDING INDUSTRY

- WATER TREATMENT PLANTS

- ALL MAJOR INDUSTRIES